Project Description

High Speed Paper Cup Making Machine(80 pcs/min) ZB-X12

Feature:

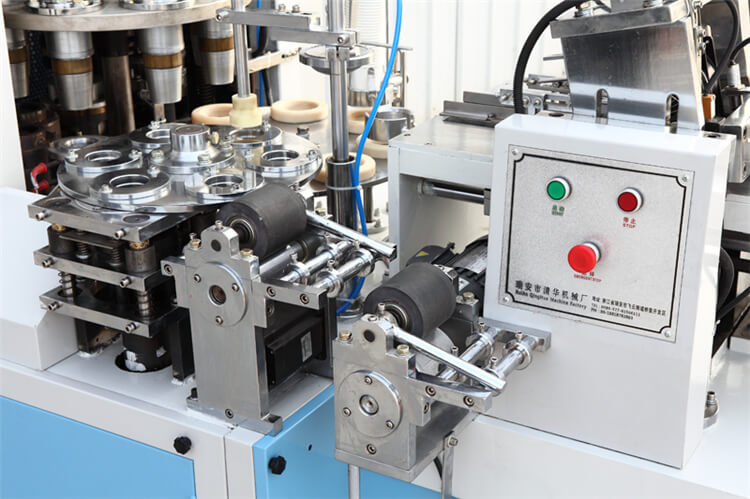

- ZB-X12 Ultrasonic Paper Cup Forming Machine is an automatic machine with multi-working station, which has the function of photocell detection, failure alarm, counter and the advantages of humanism design, safer operation and easier maintenance.

- Suitable for making paper cups for all kinds of drinks (hot and cold) disposable paper cups: paper tea cup, coffee cup, cold-beverage cup, beer cup, ice-cream cup etc.

- It makes both one-side and two-side PE-film-coated paper cups after running a whole procedure of automatic Multi-step pre-printed-cup-fan-paper Feeding (Multi-step paper-feed and Anti-back device to keep the accurate position), cup-body-side welding(ultrasonic wave), robot transfer cup body, silicone-oil lubricating(for top curling), bottom-disk punching, bottom pre-heating and pre-folding, main heating, bottom knurling(cool device for 2PE), top curling, cup discharging and collecting.

Machine Detail:

Advantage and improvement:

1. PLC program control system

Intelligent control the movement, easy operate and maintenance, Keep the machine runs smoothly, less fault and less wastage.

2. Three times paper feeding.

Better to adjust the paper fan before folded. Can make the cup looks beautiful.

3. Stepping-motor

Stepping-motor control the bottom-reel paper feeding, which keep the bottom-disk gap within 0.1mm (more stable and save paper). Program (with the sensors) keep the cup-bottom-feed corresponding to its cup-cone-body, the machine will be stopped when out of bottom-paper, avoiding the waste in paper.

4. Use Robot hand

Use Robot hand. Can improve accuracy (taking the cups to the round plate.

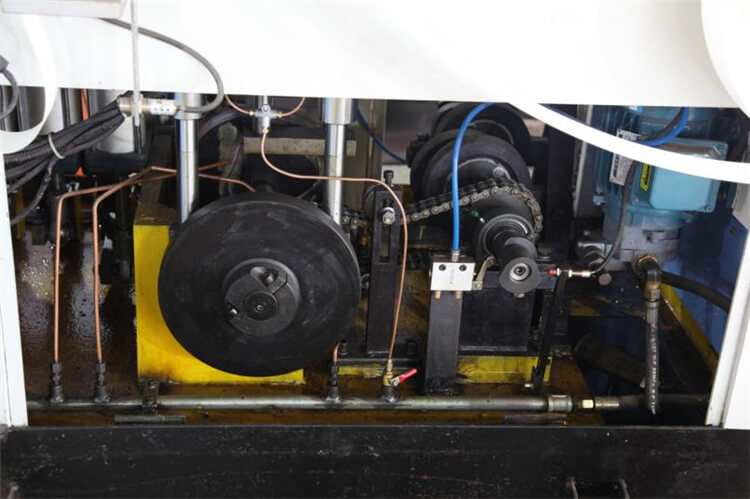

5. Self-lubrication system

Adopt self-lubrication system (auto oil circle system), automatic lubricate the move parts(bearing, axis, cam, chain, etc), keep the machine long life time (more durable) and reduce the manual maintenance, reduce the friction between the parts. So the machine can be maintained without manually fueling.

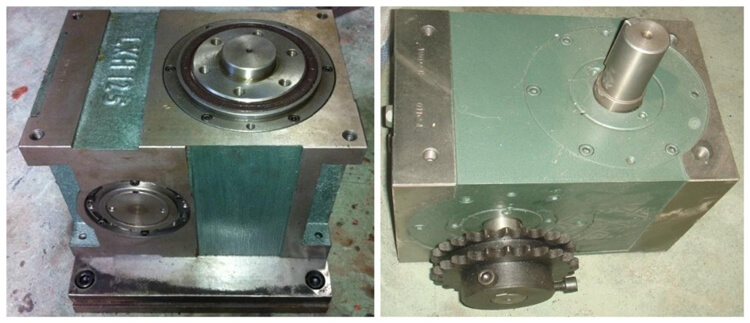

6. Adopt two model Index Gear Box ,tape125 and type80

v 125 type is much bigger and stronger than 100 type.

v 100 type gear box, if used for one year, is easier to have problem.

The gear box is very important to the machine. It control the whole machine, if there are some problems with these two parts, then, you have to change the gear box. In this case, the machine should be taken apart, because it is inside the machine. It takes much time, and sometimes you cannot install the machine correctly. So it is necessary to use better gear box.

Technical Parameter:

| Paper Cup Size: | 3oz~12oz (mold exchangeable) |

| Raw Material: | One-side or two side PE(polyethylene)film coated/laminated paper; |

| Suitable paper weight: | 180~350gsm |

| Rated Speed: | 65-80 cups/minute |

| Power Source: | 220V/380V 50Hz, (Better use 380V 3-phase) if your power is different, Please info us in advance. |

| Total Power: | 6KW |

| Total Weight: | GW/NW: 2750KG/2600KG |

| Pack Size (L*W*H) | 2800 x 1600 x 1580 mm |

| Working Air Source: | Air pressure:0.4Mpa; Air Out-put:0.6m?/minute Need to buy Air Compressor |

| Cup Side Welding: | Ultrasonic |

| Cup Bottom Heating: | Hot Air |

| Cup Bottom Knurling: | Heater Knurling (if use single PE coated paper) Cool Device (circle water) knurling, for double PE coated paper |

1 Q:What is the machine warranty?

A: One year. We will provide maintenance support for any issue with the equipment. If the equipment are still under warranty, we will replace and repair the faulty parts free of charge and buyer will only need to pay for the shipping or air charges. In general we are able to ship the faulty party that are in stock within 1 day.

2 Q:What is the delivery time?

A:15-30days after get the payment.

3 Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

4 Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

5 Q:What’s the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

6 Q:Who is going to install the equipment?

A:Generally, as a buyer you will visit our factory for equipment training and installation but if needed we could also visit buyer’s factory. Buyer only need to pay for return air ticket and lodging expenses.

7 Q: Do you accept factory visiting?

A: We are highly greeting for your visiting.

Download here:

Share Our Product, Choose Your Platform!

Why Choose us

Professional R&D Team: Over 8 years experience with a top engineer team supported

Outstanding Quality: Only choose famous brand main electric components for production

ISO CE Approved: Professional certification bodies certify that the machines are of high quality

China Service office

Mr Sam Tong

sales@dsymachinery.com

+86 13736318590

Russia Service office

Mr Дмитрий Дубков

d_dubkov@mail.ru

+7 831 27580102

Thailand Service office

Mr Thakol Yajai

info@technotestsystem.com

+662 130 6900

Australia Service office

Mr Neil Phillips

neil@ercpackaging.com.au

+61 03 9354 2022